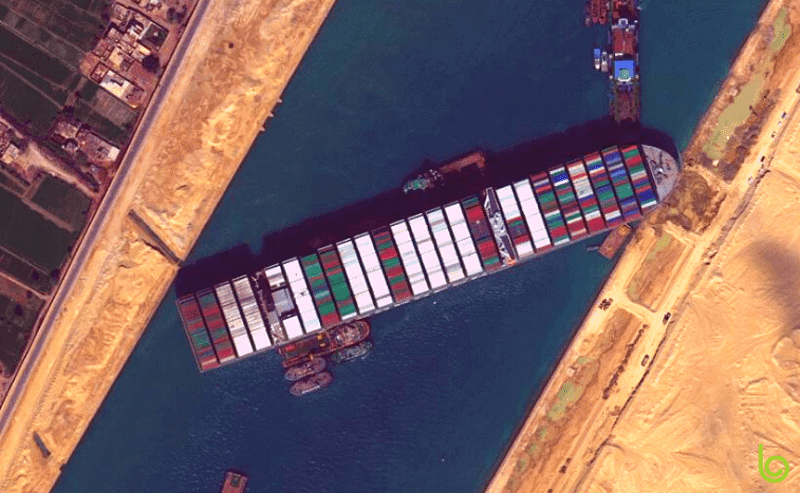

In the logistics industry, one significant chokepoint can disrupt the entire supply chain world. The most significant hitch in a while occurred when the Ever Given ran aground last week, causing a Suez Canal blockage that has impacted every corner of the supply chain. With the right supply chain technology, shippers can mitigate the impact of the disruption, finding alternate routes and modes. After six days, workers were able to partially refloat the vessel. Canal authorities were reportedly expecting it to take three days to clear the backlog of ships.

According to the BBC, the blockage cost the Suez Canal Authority around $15 million in revenue each day, and the impact to global trade is much more significant. In a report by the Wall Street Journal, a former logistics executive for Walmart told reporters that the Suez blockage will most acutely impact Europe. While the Suez Canal is primarily used to route goods from Asia to Europe, the blockage will certainly have an impact in the U.S.

“It’s not a stretch to say that the blockage at the Suez Canal could have significantly impacted the entire global freight transportation world,” said Michael Moore, chairman of the board at Fenix Marine Services and a member of the Blume Global executive advisory board. “The impact is easy to see if you think of the supply chain as a series of choreographed steps moving at the same speed on a global basis and using proven and tested routes. If one of the movements gets stuck, particularly if it’s one of the main arterial routes, that becomes a huge issue for the rest of the system. Unfortunately, the problems won’t all emerge right away. When the system is no longer harmonized, movement will slow down and stop proceeding in a synchronized manner, thus affecting the entire global supply chain.”

Late last week, carriers began routing vessels around the Cape of Good Hope, adding nearly two weeks onto transit times. Airfreight was being considered for some of the shipments, but switching modes isn’t always financially viable.

“It might seem like air cargo is a no-brainer for shippers that would normally send goods through the Suez, but the cost increase from ocean shipping to air transportation is significant. There are only a few types of commodities that can absorb that cost difference,” Moore said. “And the cost is irrelevant if shippers can’t find air capacity, which has been highly constrained throughout the pandemic due to the lack of belly capacity in passenger aircraft.”

For some commodities, the “belt and road” rail connection between China and Europe could have offered an alternative route, but that connection is also very in the demand due to the ramp-up in consumer ordering during the COVID-19 pandemic. There now exist capacity issues and border congestion at this route too.

Blockages have occurred before. In the early 1990s, carriers were forced to route vessels around the cape due to disruptions caused by the Gulf Conflict. Another crisis was avoided in 2013 when a series of tugboats prevented the Emma Maersk, which was the largest container vessel in the world at that time, from wedging itself diagonally across the waterway. COVID has made the impact worse.

So what can shippers do to get around the current mess? Supply chain technology provider Blume Global has a logistics execution and visibility platform that allows en-route shipments to move to alternate modes, carriers or service levels when those shipments are going to be late. Blume Maps, a digital twin of the supply chain world, makes planning a freight shipment’s route and changing course during the journey if problems arise as natural as using a navigation app during a family road trip.

Blume Maps works by providing intelligent data on more than 1.5 million locations around the world and combining that information with dynamic scheduling and routing information, giving shippers increased route planning abilities. While it might not help shippers with goods currently stuck in the canal, stakeholders who had normally used the route can dynamically weigh variables such as lead times, cost implications, and historical data to estimate transit times before the shipment is sent.

With Blume Maps, shippers and 3PLs can plan, track and adjust multi-modal shipments all over the globe from a single digital operating system. Sign up for a demo to see how Blume Maps can bring agility and unrivaled logistics execution to your supply chain.

contact us

Contact Us