We’re now only a few days away from Black Friday, one of the biggest retail holidays of the year—and with it comes one of the busiest seasons for the shipping industry. This year, the National Retail Federation estimates that 165.3 million people will shop Thanksgiving Day through Cyber Monday, with Black Friday accounting for about 114.6 million shoppers. With the high demand brought on by the season, every stakeholder within the supply chain is strained.

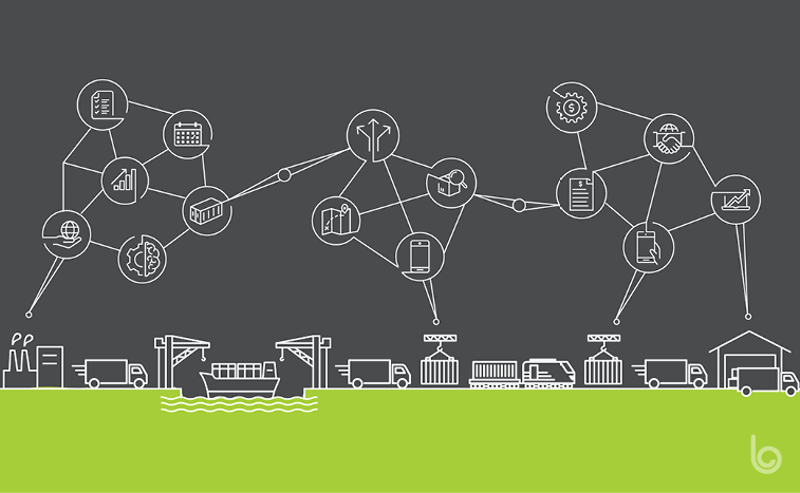

In this series we’ll be sharing some of the biggest challenges that the supply chain industry is facing and how we can tackle these problems with innovative technology. For the first part of our series we will be discussing the increasing complexity and fragmentation of shipment journeys in light of the holiday season.

Prepping Centers & Returns Add More Stops in the Supply Chain

In order to keep up with high customer demand brought on by events like Cyber Monday, e-commerce sites like Amazon have begun to enlist prepping centers, which receive and repackage products from third party retailers to sell for these sites. Though prepping centers tend to be small businesses, they account for about 60 percent of sales on Amazon. However, prepping centers add another layer of complexity to an already fragmented supply chain. Rather than a product going straight from the seller to the e-commerce site, there is an additional stop in the product’s route to the customer.

With more purchases made during this holiday season, an inevitable effect is the increase of returns made by consumers. Many e-commerce retailers are partnering with physical stores, such as Walgreens and CVS, to enable customers to make in-person returns. Thus, returns further fragment the supply chain, as they no longer go directly back to the e-commerce site. This new practice is largely driven by the demand created by consumers for easy returns.

Dynamic Mapping Solving Complexities of Supply Chain Moves

Given the high demand of the holiday season, e-commerce sites are going to need to heavily rely on prepping centers for inventory and other physical retailers to manage returns. In order to ensure that products are delivered efficiently and in the estimated time to their final locations, companies should look to and implement technologies that make a significant impact, such as dynamic mapping.

By utilizing dynamic mapping, retailers can gain real-time visibility on their products, receiving exception alerts and recommendations, such as dynamic predictive ETA. In addition, use of solutions like dynamic mapping provides real-time analysis, based on data from inside and outside their network, delivering the most accurate dynamic visibility available. Retailers will then be able to get shipments back on track before potential issues become a reality.

To make sure that your supply chain organization is best prepared for the holiday season, learn about how Blume Visibility can give you physical and financial supply chain visibility for shipments, inventory and costs. Also stay up-to-date on the latest technologies by subscribing to our learning center articles here.

contact us

Contact Us